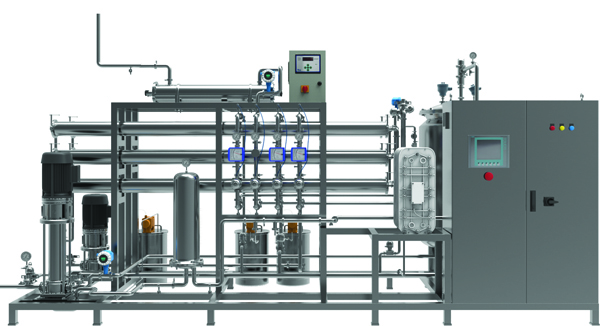

MEDICELL® – Spore & Virus Free Water System for Microbiological Research and Cell Cultivation

The MEDICELL® system is a complete solution comprising pre-treatment, distillation,

storage, distribution, and dispensing. All components in contact with the distillate

are manufactured from borosilicate glass, titanium, or PTFE.

The produced distillate is free from bacteria, toxins, viruses, spores, DNA, and RNA.

The system is fully closed from the incoming feed water to the final container or bottle,

ensuring absolute cleanliness and sterility. Distribution and dispensing are performed

at ambient temperature through a specially designed system.

A dedicated washing machine is supplied with the system to guarantee that all bottles

or items are thoroughly cleaned before filling. Years of independent laboratory testing

have demonstrated excellent research results, reducing spontaneous infections and ensuring

consistent growth rates in cell cultures.

Design Features

- Completely closed system up to user points

- Integrated quality assurance system

- Unique dispensing design

- Storage and distribution at ambient temperature

- No regular sterilisation required

- Easy installation

Available System Capacities – Electrically Heated

- E-8-C — 8 L/h, with max. storage tank size 200 L

- E-25-C — 25 L/h, with max. storage tank size 600 L

- E-50-C — 50 L/h, with max. storage tank size 1200 L

PLC Automation

- Fully automatic operation

- Automatic start/stop based on storage tank signal

- User point regulation

- Discharge of sub-standard distillate during start, operation and stop

- Automatic surveillance and alarms for critical process values

Factory Acceptance Testing (FAT)

All AQUA-NOVA® stills undergo FAT testing at our factory before delivery.

Each test is documented, and distillate quality is verified by an independent laboratory.

The software is developed according to GAMP specifications.

Upon request, full SAT, IQ and OQ documentation is supplied, including calibration certificates.

The standard delivery documentation includes:

- Authorised drawings with material and weld certificates

- Mechanical component documentation and manuals

- Electrical and instrumentation documentation and manuals

- Installation, operation and service manual