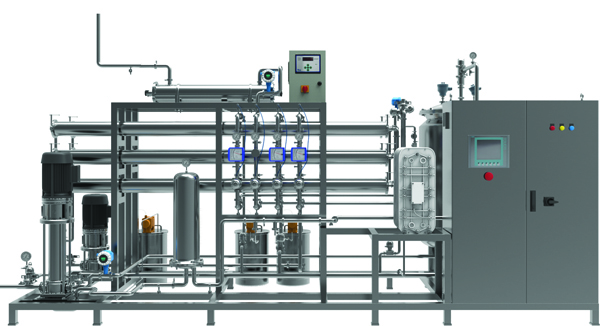

Purified Water RO Units – Single or Double Pass in Combination with CEDI and UF

AQUA-NOVA RO units are engineered to deliver optimized functionality and safe water quality

exceeding the latest USP and EP requirements for Purified Water (PW) and Cold WFI.

Each system is individually dimensioned based on required capacity, target quality, and a complete raw water analysis.

Design Features

- Fully automatic operation and surveillance

- High operational safety

- Flexible configuration

- Hot water sanitation and integrated CIP system

- Skid-mounted design for easy installation

Pre-Treatment – 200 to 10,000 L/h

- Multi-media filtration

- Iron removal

- Softeners

- Dosing systems

- Fine particle filtration

RO Systems – Double Pass, 200 to 7,000 L/h

- Full-fit membranes

- Membrane housings in AISI 316L

- Piping in AISI 316L or CPVC

- Integrated CIP system

RO + CEDI Systems – 200 to 7,000 L/h

- Full-fit membranes

- Membrane housings in AISI 316L

- Piping in AISI 316L or CPVC

- Thick plate type CEDI modules

- Integrated CIP system

PLC Automated Standard Functions

- Automatic start/stop based on PW tank signal

- Manual start/stop option

- Discharge of sub-standard PW or HPW during start, operation and stop

- Automatic valve regulation of all media

- Automatic surveillance and alarms for critical process values

Example of Optional Equipment

- Hot water sanitation system

- Sterile air vent filter with close-off function

- Self-sterilisation cycles and valves

- Heat steam safety relief valve and pressure shut-off

- Distillate aftercooler to desired temperature

- Electropolished internal surfaces

- Boroscope inspection of internal welds

- Central control cabinet for complete PW system

- PW storage tanks and distribution loop systems

Factory Acceptance Testing (FAT)

All AQUA-NOVA RO units are FAT-tested at our factory before delivery. Each test is documented,

and the produced PW or HPW quality is verified by an independent laboratory.

The software is developed in accordance with GAMP specifications.

Upon request, full SAT, IQ and OQ documentation is supplied, including calibration certificates.

The standard delivery documentation includes:

- Material and weld certificates

- Mechanical component documentation and manuals

- Electrical and instrumentation documentation and manuals

- Installation, operation, and service manual