The units have a number of design features to achieve an optimised function and a safe distillate quality exceeding the latest editions of USP and EP for Water For Injection.

DESIGN FEATURES

* Fully automatic function and surveillance.

* Unique 4 step separation system.

* Maximal operational safety.

* High flexibility

* Pure Steam production possible

* Space saving, easy to install

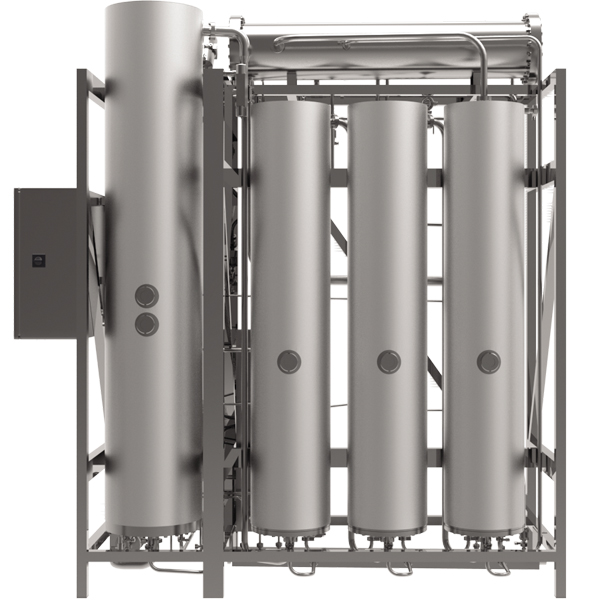

SINGLE EFFECT STILLS

S-50/150-C, steam heated, production:

Distillate, 90ºC, 50 – 150 L/h, using 2 – 6 bar g

E-50-C, electrically heated, production:

Distillate, 90ºC, 50 L/h, 35 kW

E-8-C, electrically heated, production

Distillate, 90ºC, 8 L/h, 6 kW

Other capacities are available on request!

PLC AUTOMATED STANDARD FUNCTION

* Automatic start/stop on signal from WFI tank.

* Discharge of sub-standard distillate during start,…operation and stop.

* Automatic valve regulation of heating steam,…feed and cooling waters as well as compressed air.

* Automatic surveillance & alarms of critical process…values.

EXAMPLE OF OPTIONAL EQUIPMENT

* Automated or manual valves for Pure Steam..production.

* Pure Steam sample condenser.

* Sterile air vent filter and close off.

* Self sterilisation cycle and valves.

* Heat steam safety relief valve & pressure shut off.

* Distillate ”after” cooler to desired temperature.

* Electro polished internal surfaces.

* Boroscope inspection of internal welds.

* Central control cabinet for the complete WFI system.

* WFI storage tanks and loop systems.

FACTORY ACCEPTANCE TESTING

All AQUA-NOVA stills are production FAT tested at our factory before delivery. The tests are documented and the produced distillate quality is verified by an independent laboratory.

The software is developed as per GAMP specifications.

When ordered, full Pre IQ and OQ documentation will be

supplied with the machines, including calibration documents.

The standard delivery documentation consists of:

* Authorised pressure vessel drawings with material

..and weld certificates.

* Mechanical component documentation and manuals.

* Electrical and instrument documentation and manuals.

* Machine installation, operation and service manual

The units have a number of design features to achieve an optimised function and a safe distillate quality exceeding the latest editions of USP and EP for Water For Injection.

DESIGN FEATURES

* Fully automatic function and surveillance.

* Unique 4 step separation system.

* Maximal operational safety.

* High flexibility

* Pure Steam production possible

* Space saving, easy to install

SINGLE EFFECT STILLS

S-50/150-C, steam heated, production:

Distillate, 90ºC, 50 – 150 L/h, using 2 – 6 bar g

E-50-C, electrically heated, production:

Distillate, 90ºC, 50 L/h, 35 kW

E-8-C, electrically heated, production

Distillate, 90ºC, 8 L/h, 6 kW

Other capacities are available on request!

PLC AUTOMATED STANDARD FUNCTION

* Automatic start/stop on signal from WFI tank.

* Discharge of sub-standard distillate during start,…operation and stop.

* Automatic valve regulation of heating steam,…feed and cooling waters as well as compressed air.

* Automatic surveillance & alarms of critical process…values.

EXAMPLE OF OPTIONAL EQUIPMENT

* Automated or manual valves for Pure Steam..production.

* Pure Steam sample condenser.

* Sterile air vent filter and close off.

* Self sterilisation cycle and valves.

* Heat steam safety relief valve & pressure shut off.

* Distillate ”after” cooler to desired temperature.

* Electro polished internal surfaces.

* Boroscope inspection of internal welds.

* Central control cabinet for the complete WFI system.

* WFI storage tanks and loop systems.

FACTORY ACCEPTANCE TESTING

All AQUA-NOVA stills are production FAT tested at our factory before delivery. The tests are documented and the produced distillate quality is verified by an independent laboratory.

The software is developed as per GAMP specifications.

When ordered, full Pre IQ and OQ documentation will be

supplied with the machines, including calibration documents.

The standard delivery documentation consists of:

* Authorised pressure vessel drawings with material

..and weld certificates.

* Mechanical component documentation and manuals.

* Electrical and instrument documentation and manuals.

* Machine installation, operation and service manual